As Technology Continues to Evolve, So Has

Baomit's Dedication to Serving Markets.

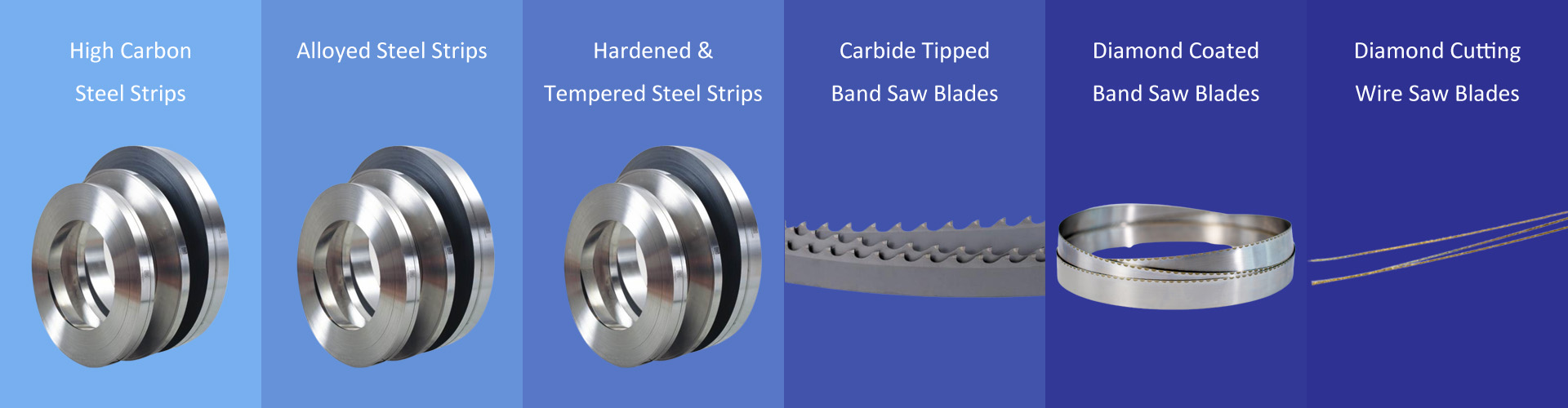

Baomit is an industry-leading precision strip steel & band saw blade supplier for manufacturers of diversified products

in aerospace, automotive, oil & gas, power generation, and other industrial markets.

Aerospace Applications

Baomit supplies precision steel strips specifically engineered for aerospace products that can withstand and perform in the most challenging conditions.

At Baomit, our team of experts use the state-of-the-art equipment and expertise to creat the strip coils as required for the aerospace industry. In general, we produce the lighter, stronger, and more precise steel strips and foils.

Automotive Applications

As technology continues to evolve the automotive industry, so has Baomit’s dedication to serving the market.

Supported by our team’s expertise and the state-of-the-art equipment, we are capable of supplying high-strength steel strips with the special properties that are necessary for you and your automotive needs. Components made possible with Baomit such as: clutch parts, brake parts, safety buckles, bearing parts, automatic transmission parts.

Oil & Gas Applications

Oil & Gas Applications

Products used in the oil & gas industry are subject to some of the harshest environmental conditions in the world. It's a necessity that our materials perform in these extreme environments.

At Baomit, we take pride in our manufacturing capabilities and reliable partnerships with our customers. Our experienced processing capability gives our customers access to the tighter tolerances with higher precision.

Power Generation Applications

Power Generation Applications

As countries and industries are making efforts in reducing air pollution and carbon emmissions, fuel cells are becoming an increasingly popular alternative to combustion engines for clean power generation.

Types of fuel cell products made possible with Baomit:

• Consumer Vehicles

• EV Charging Systems

• Backup Power Generations

Semiconductor Applications

Semiconductor Applications

The polysilicon price in the semiconductor industry is very expensive, and the traditional band saw blades are prone to chipping and have high vibration in the process of cutting, and the cutting seam is large.

Diamond band saw blades are specifically designed, produced by Baomit in cutting hard, brittle and fibrous materials. Our blades feature higher cutting efficiency, smoother cutting with lower vibration and less material waste.

Optical Applications

Optical Applications

Super-hard materials such as sapphire, quartz, KPD, and other artificial lenses, are very difficult to cut. Baomit's diamond cutting wire saw blades, due to its ultra-high linear speed and numerous cutting edges, can greatly improve cutting efficiency and surface quality.

We are dedicated to partnering with forward-looking companies and providing personalized material solutions to suit your precise needs and manufacturing processes.

Looking for an experienced materials partner to extend your supply chain?

Rich experience working with metals in multiple industries, has led us to the forefront in applications. You’ll be assisted by our team of experts each time, enabling you to establish a strong working relationship.