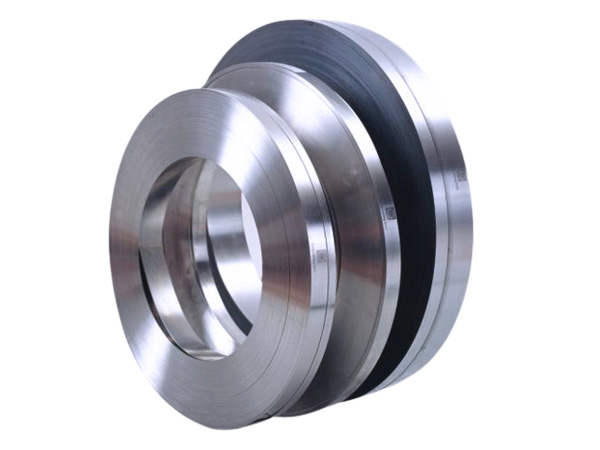

51CrV4 SAE6150 COLD ROLLED ALLOY STEEL STRIP

Alloy steel strips are used whenever standard high carbon steel grades cannot reach the requested results. Different grades contain specific alloyed elements to emphasize the main properties which are important for specific applications. Different values can be discussed with our team of experts that will help our customers to get better results in their production.

| USA | EU | C | Si | Mn | P | S | Cr | Mo | V |

| 6150 | 51CrV4 | 0.47 - 0.55 | Max 0.40 | 0.70 - 1.10 | Max 0.025 | Max 0.025 | 0.90 - 1.20 | 0.10 - 0.25 |

Supply Conditions: Cold Rolled, Annealed, Spheroidize Annealed, Hardened & Tempered.

Thickness: 0.15-2.50mm

Width: 8.00-300.00mm

Hardness: 29-55HRC

Surface: nature, polished, blue, yellow, black

Edge: slit, sheared, square, rouned

Hubei Baomit Steel Materials Co., Ltd.

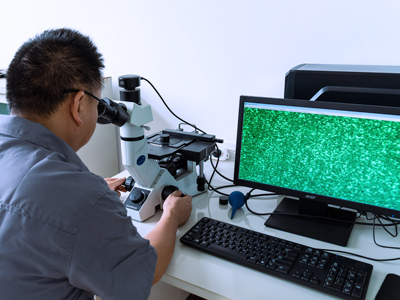

Baomit excels as the global leader and an expert in cold rolled precision steel strips since 2011. Our experienced processing capabilities give our customers access to the tighter tolerances with higher precision. Baomit’s team of experts personalize material solutions to suit your precise needs and manufacturing processes. We offer precision steel strips, foils, aligned with reliable delivery for multiple applications in a variety of industries, including aerospace, automotive, oil & gas, power.

Our Service Center Processing Capabilities

Looking for an experienced materials partner to extend your supply chain?

Rich experience working with cold rolled precision steel strips in multiple industries, has led us to the forefront in applications. You’ll be assisted by our team of experts each time, enabling you to establish a strong working relationship. Contact a Specialist!

YOU MAY ALSO BE INTERESTED IN THESE PRODUCTS