High Performance Band Saw Blade Manufacturer

The Expert in Cutting Hard and Brittle Materials

Baomit offers a wide range of high quality super-hard cutting tools aligned with reliable delivery for multiple applications in a variety of industries. By utilizing the state of the art processing equipment, we’re dedicated to being a premier producer and leadership in band saw blades, with each order expertly manufactured to your exact specifications.

BAOMIT | Diamond Cutting Blades

Diamond cutting blades are specifically designed to cut hard, brittle, and fibrous materials. The unique properties of the backing materials produced by Baomit are perfectly suited for withstanding the stresses caused by these extremely high cutting speeds.

DIAMOND BAND SAW BLADES

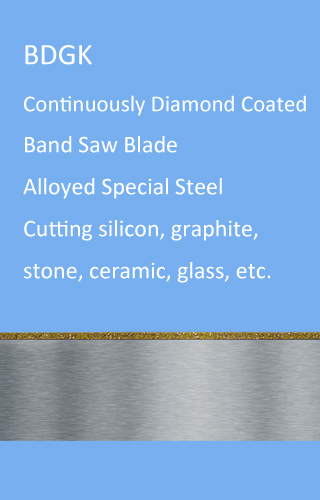

BDGK Continuously Diamond Coated Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Alloyed Special Steel

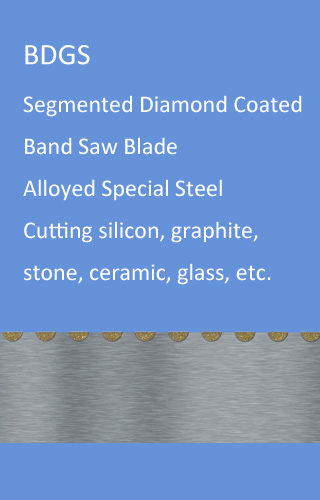

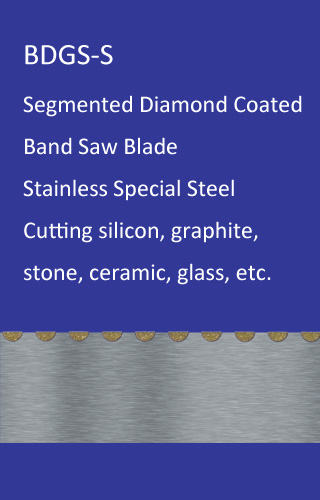

BDGS Segmented Diamond Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Alloyed Special Steel

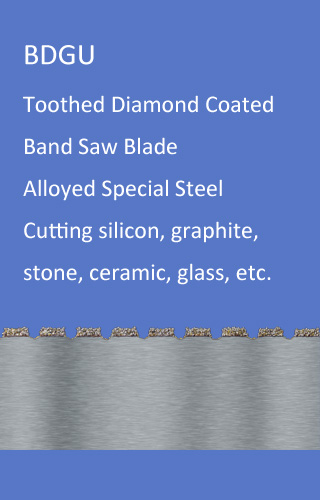

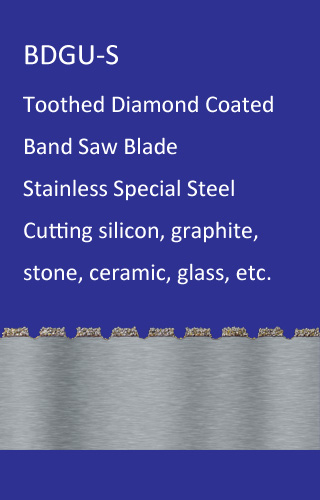

BDGU Toothed Diamond Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Alloyed Special Steel

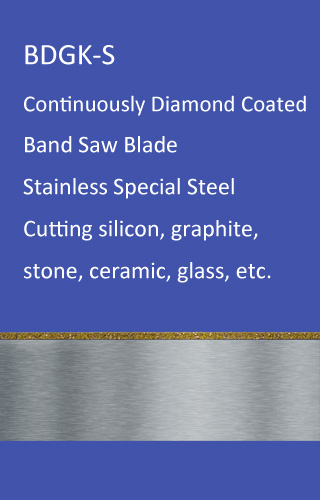

BDGK-S Continuously Diamond Coated Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Stainless Special Steel

BDGS-S Segmented Diamond Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Stainless Special Steel

BDGU-S Toothed Diamond Blade for Cutting Silicon, Graphite, Stone, Ceramic, Glass, Stainless Special Steel

Features

• Continuous / Segmented / Toothed diamond coating on the band edge

• Customized grain sizes

• Backing material made of alloyed special steel / stainless steel

Advantages

• Higher cutting efficiency

• Cutting is more durable, faster

• Smoother cutting with lower vibration

• Minimizing material waste

Applications

• Monocrystalline silicon, polysilicon

• Sapphire, stone, ceramic, glass

• Graphite, graphite carbon, concrete materials

Sizes

| Length mm | Width mm | Thickness mm | Grain Size |

| 3230 | 38 | 0.40 | 80/100, 100/120 |

| 3230 | 38 | 0.60 | 80/100, 100/120 |

| 3750 | 38 | 0.60 | 80/100, 100/120 |

| 4550 | 38 | 0.70 | 80/100, 100/120 |

| 4800 | 38 | 0.70 | 80/100, 100/120 |

| 6090 | 38 | 0.70 | 80/100, 100/120 |

| 1565 | 6 | 0.30 | 120/140, 140/170 |

| 2390 | 8 | 0.30 | 120/140, 140/170 |

| 2700 | 10 | 0.30 | 120/140, 140/170 |

| 3750 | 40 | 0.40 | 120/140, 140/170 |

| 4260 | 40 | 0.40 | 120/140, 140/170 |

Contact a Specialist

Due to the rather unique applications of diamond cutting blades, we generally recommend that you contact us for advice on grain sizes to coordinate combinations of grain size and diameter of the blade to suit your application. Our specialist will get in touch with you soon!

BAOMIT | Carbide Cutting Blades

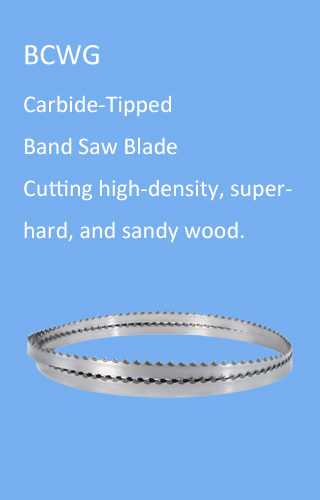

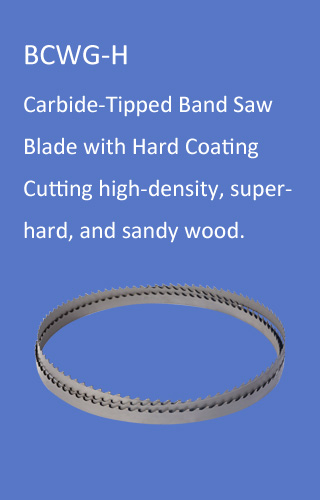

Super-hard wood grade carbide blades are best suited for high-density, super-hard, and sandy wood cutting. Special hard material coating can be additionally provided for considerable increase in machining performance in the event of capacity bottlenecks.

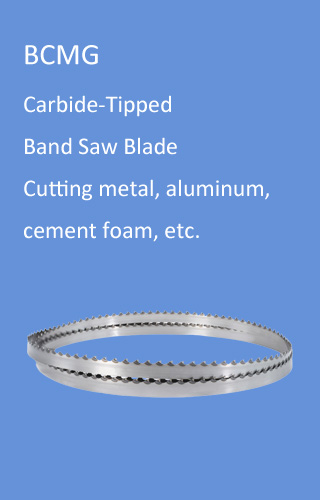

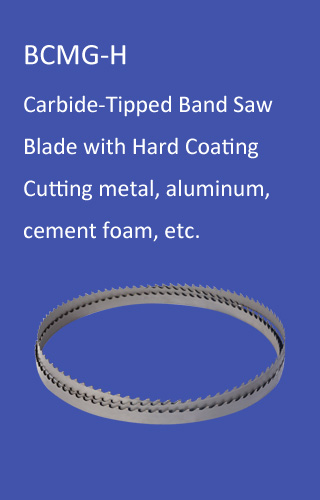

Metal grade carbide blades are designed to cut metals or non-ferrous metals, specifically aluminum, cement foam. Depending on the carbide grade chosen, these blades are best suited for cutting metal, aluminum, cement foam, etc. Depending on your cutting application you may opt for teeth coated with a special material to increase cutting performance and extend the blade’s overall life.

CARBIDE BAND SAW BLADES

BCWG Carbide Tipped Blade for Wood Cutting, Alloyed Special Steel

BCMG Carbide Tipped Blade for Metal Cutting, Alloyed Special Steel

BCWG-H Carbide Tipped Blade with Hard Coating for Wood Cutting, Alloyed Special Steel

BCMG-H Carbide Tipped Blade with Hard Coating for Metal Cutting, Alloyed Special Steel

Features

• Special carbide-tipped

• Polished trapezoid tooth with positive rake angle

• Special hard coating for considerable increase in machining performance

Advantages

• Extremely resistant to abrasive wear

• Smaller cutting gap

• High cutting performance

• Long running times

Applications

• Metal

• Aluminum

• Foam concrete

• Super-hard wood

Sizes

| Length mm | Width mm | Thickness mm |

| 6050 | 100 | 1.05 |

| 7100 | 100 | 1.05 |

| 8230 | 125 | 1.10 |

| 9650 | 125 | 1.25 |

| 11700 | 150 | 1.25 |

| 3800 | 30 | 0.90 |

| 4150 | 40 | 0.90 |

| 4550 | 40 | 0.90/1.0 |

| 4650 | 50 | 0.90/1.0 |

| 5490 | 55 | 1.0 |

| 6030 | 60 | 1.0 |

Contact a Specialist

Rich experience working with super-hard cutting tools in multiple industries, has led us to the forefront in applications. You’ll be assisted by our team of experts each time, enabling you to establish a strong working relationship.