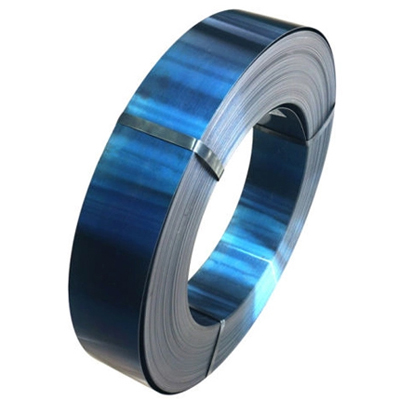

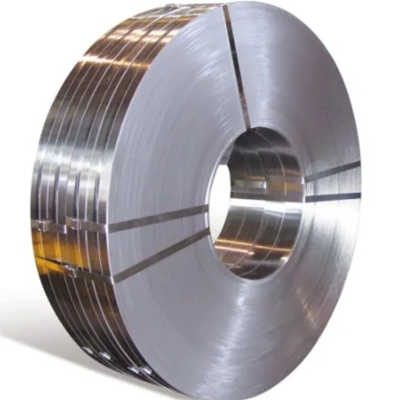

Hardened Tempered High Carbon Steel Strips

Baomit’s production team properly harden and temper high carbon steel strips to satisfy the most demanding specifications of our customers. The strength, durability and flexibility of high carbon steel make it suitable for many high strength applications. The particular AISI/SAE 1075 & 1095 high carbon steel we offer are used by the automotive, blade, and aerospace industries, for example, and in the manufacture of products like blades, power springs, saws, automotive parts, washers, and more.

| Parameters | Recommendation |

| Thickness Tolerance | T1 – T5 |

| Roughness | Class 1 – 3 |

| Flatness | Class 1 – 4 |

| Surface | Bright, White / Blue / Yellow Polished |

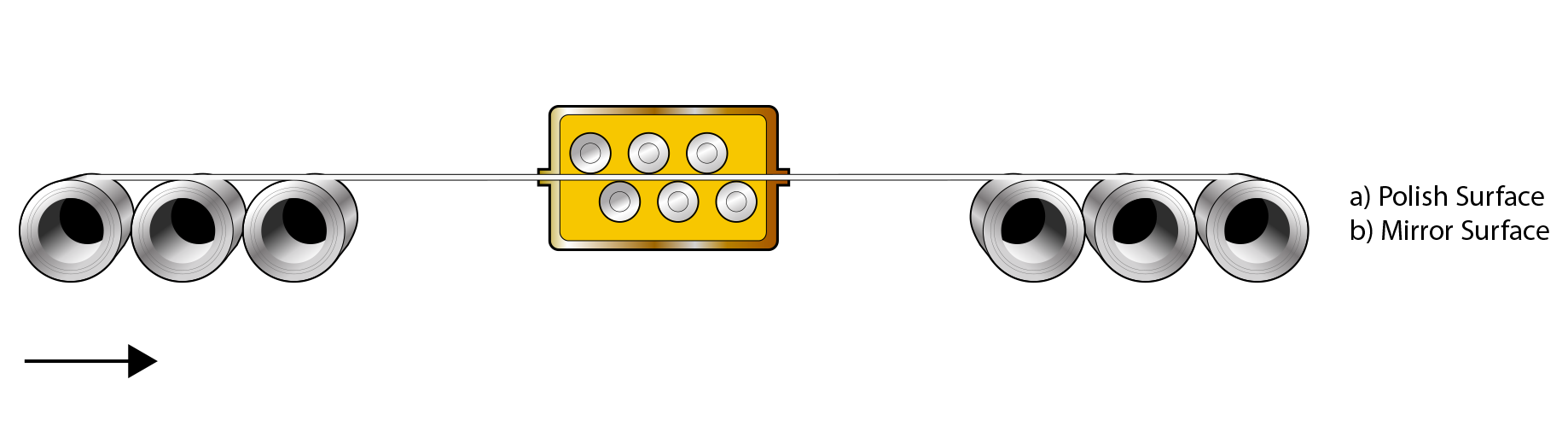

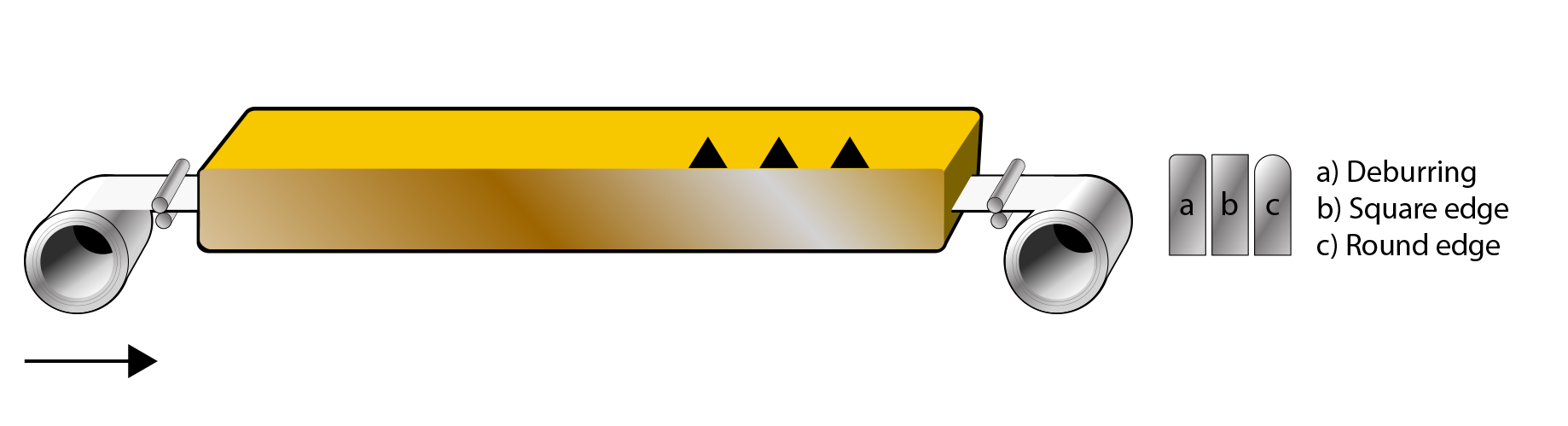

| Edges | Deburring, Square, Round |

| Hardness | 41 – 57 HRC |

| Thickness | 0.10 – 4.50 mm |

| Width | 3 – 460 mm |

| Steel Grade | 1050, 1055, 1075, 1095, SK5, SK4, SK2, C67S, C75S, C100S |

Our Advantages:

• Precise thickness and width tolerances

• Maximum straightness deviation of 1 mm / 6 m

• Good surface finish

• Excellent punching and stamping properties

• Consistent, uniform microstructure

Steel Grades

| Comparison of Norms | ||

| USA / AISI | EU / EN | Chemical Composition |

| SAE1075 | C75S | C: 0.70-0.80, Si: 0.15-0.35, Mn: 0.60-0.90, Ni: max 0.40, P: max 0.025, S: max 0.025, Cr: max 0.40, Mo: max 0.10 |

| SAE1095 | C100S | C: 0.95-1.05, Si: 0.15-0.35, Mn: 0.30-0.60, Ni: max 0.40, P: max 0.025, S: max 0.025, Cr: max 0.40, Mo: max 0.10 |

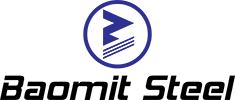

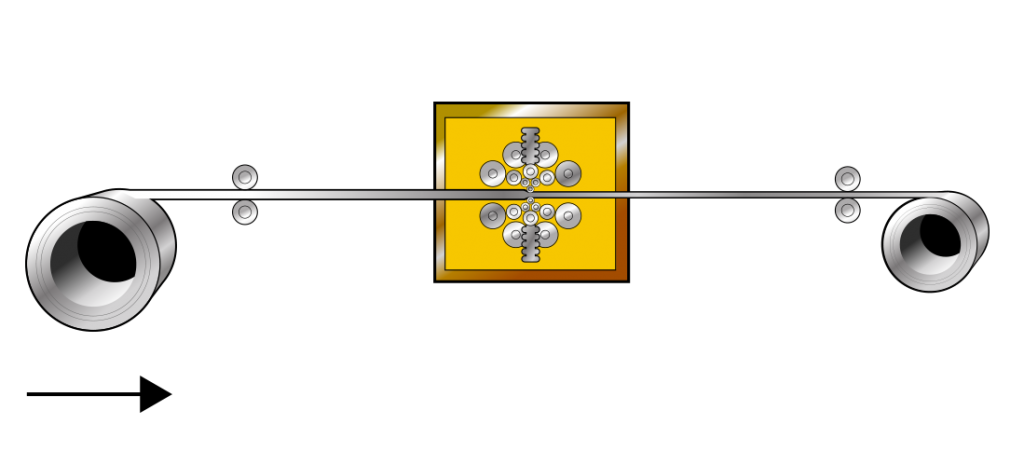

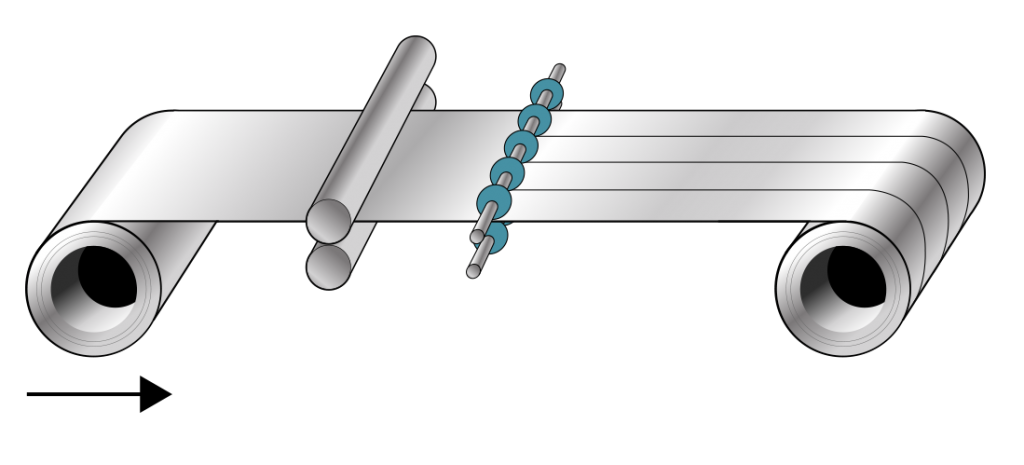

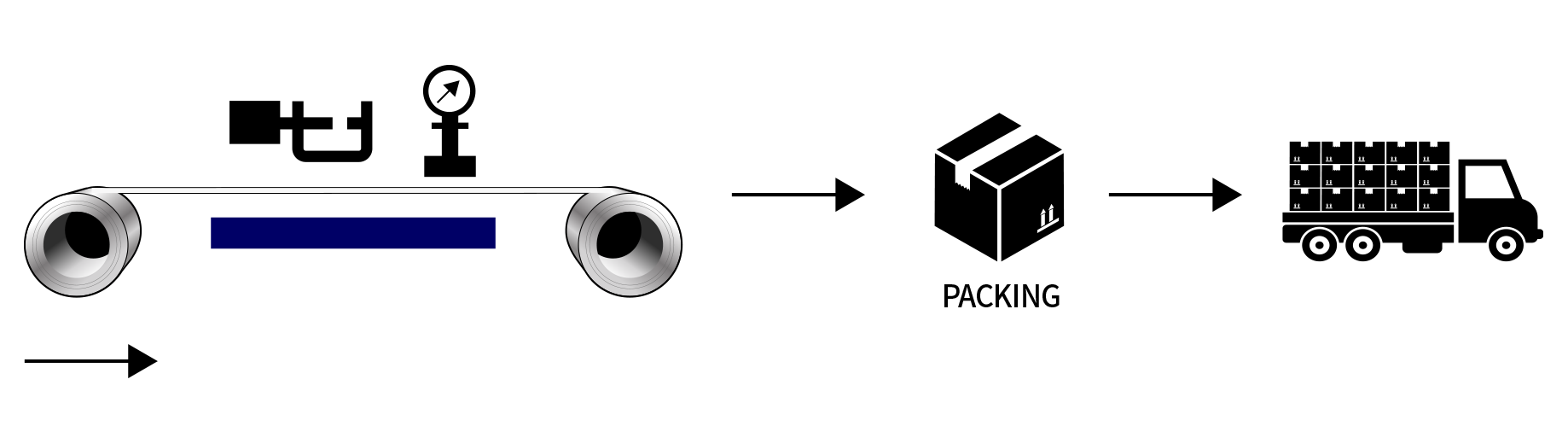

Manufacture Process

Thickness Tolerances

Width Tolerances

Surface Roughness

Flatness Deviation

Straightness Deviation

Hubei Baomit Steel Materials Co., Ltd.

Leading manufacturer of hardened and tempered high carbon steel strips 1075/1095/C67S/C75S/C100S/SKS51/SK4/SK5.

Baomit strip steel stands for precision, quality and high performance. Our material is excellent in terms of comprehensive delivery indicators, such as straightness, flatness, mechanical properties and metallographic uniformity.