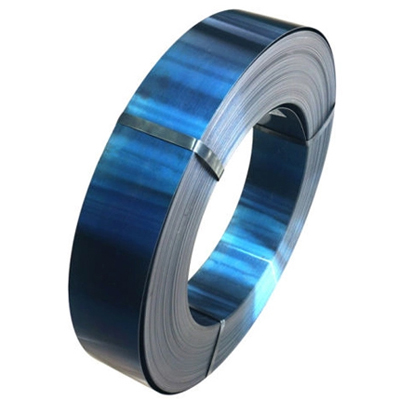

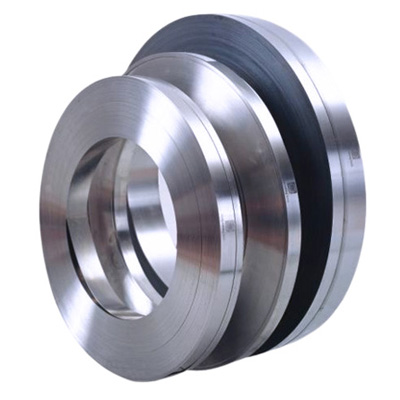

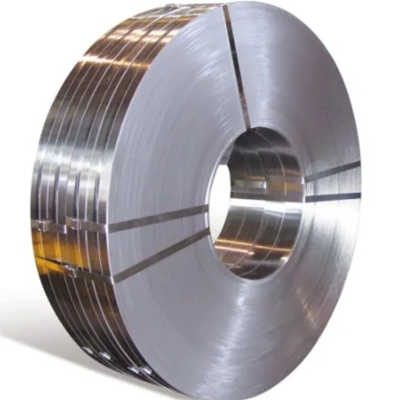

Hardened Tempered Spring Steel Strips

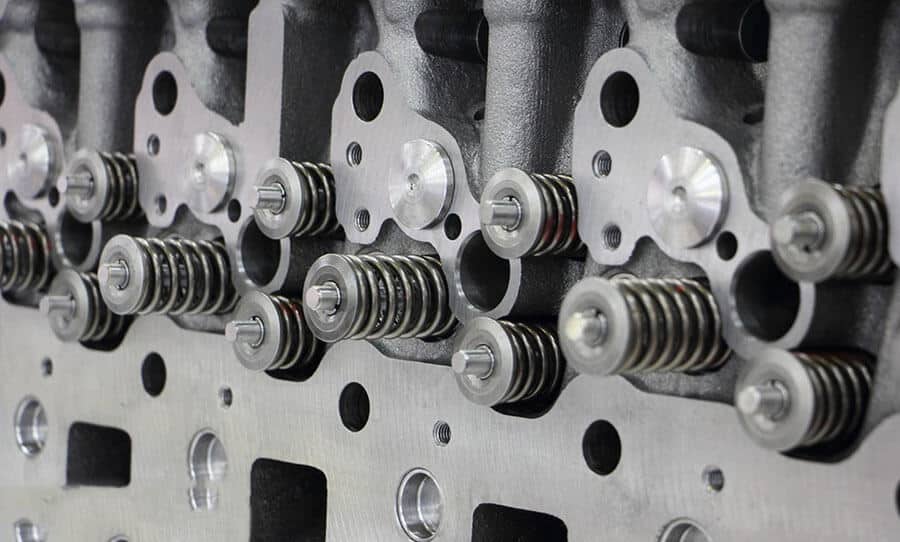

Spring steel strip is a type of steel that is specifically used to make springs, strippers, scrapers, and elastic parts because it can return to its original shape after bending, compression, or extension. This ability, known as elasticity in the quenched and tempered state, arises due to the high yield strength of the steel, which comes from its specific composition and hardening process. Fabricating spring steel requires advanced technical skills to ensure high quality. Any defects on the surface, such as decarburization or irregularities, can reduce fatigue strength. Baomit strip steel ensures that the springs have a perfectly smooth surface for optimal efficiency and performance.

| Parameters | Recommendation |

| Thickness Tolerance | T2 – T3 |

| Roughness | Class 3 |

| Flatness | Class 3 |

| Surface | Bright, White / Blue / Yellow Polished |

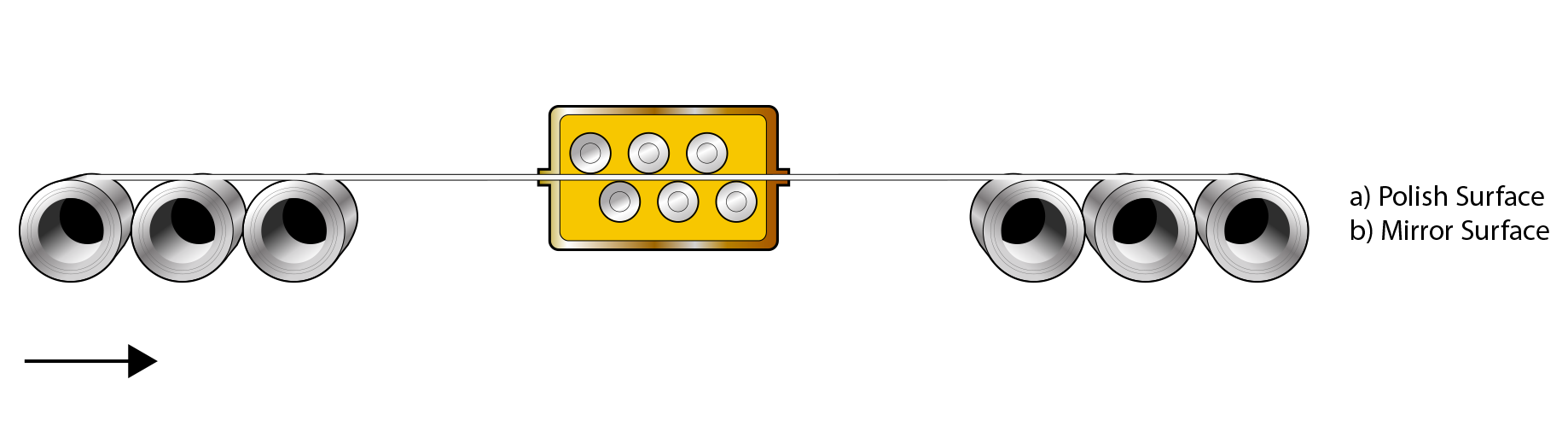

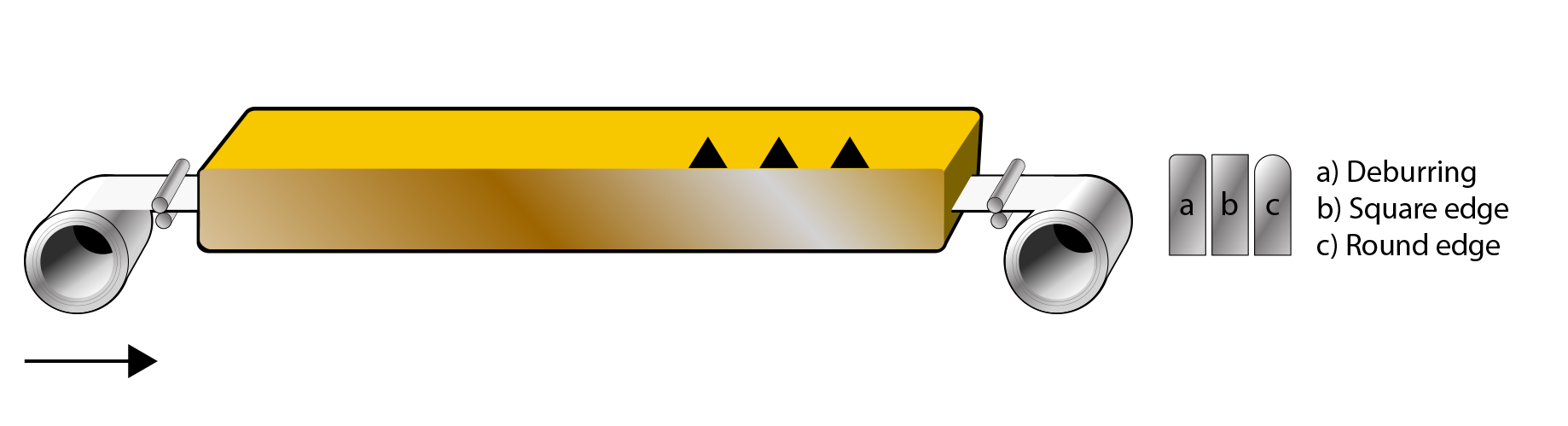

| Edges | Deburring, Square, Round |

| Hardness | 44 – 52 HRC |

| Thickness | 0.10 – 4.50 mm |

| Width | 3 – 460 mm |

| Steel Grade | C67S, C75S, C100S, 50CrV4 |

Our Advantages

• Excellent fatigue resistance

• Excellent punching and stamping properties

• Precise thickness and width tolerances

• Maximum straightness deviation of 1 mm / 3 m

• Good surface finish

• Consistent, uniform microstructure

Steel Grades

| Comparison of Norms | ||

| EU / EN | USA / AISI | Chemical Composition |

| C67S | 1070 | C: 0.65-0.73, Si: 0.15-0.35, Mn: 0.60-0.90, Ni: max 0.40, P: max 0.025, S: max 0.025, Cr: max 0.40, Mo: max 0.10 |

| C75S | 1075 | C: 0.60-1.20, Si: max 1.0, Mn: max 1.0, Ni: max 0.60, P: max 0.04, S: max 0.03, Cr: 16.0-18.0, Mo: max 0.75 |

| 50CrV4 | 6150 | C: 0.47-0.55, Si: max 0.40, Mn: 0.70-1.10, P: max 0.025, S: max 0.025, Cr: 0.90-1.20, V: 0.10-0.25 |

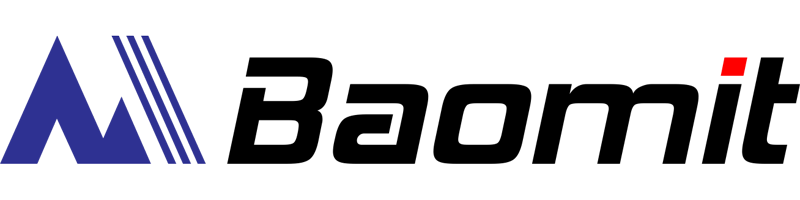

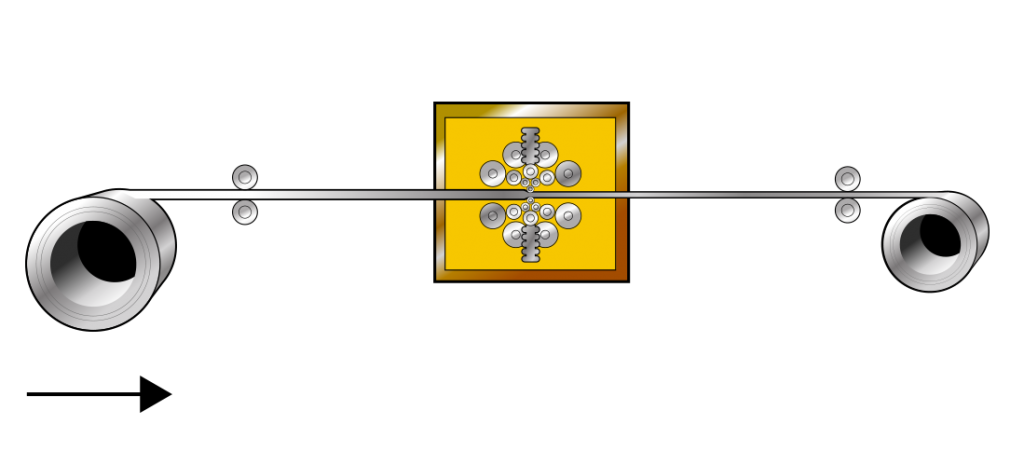

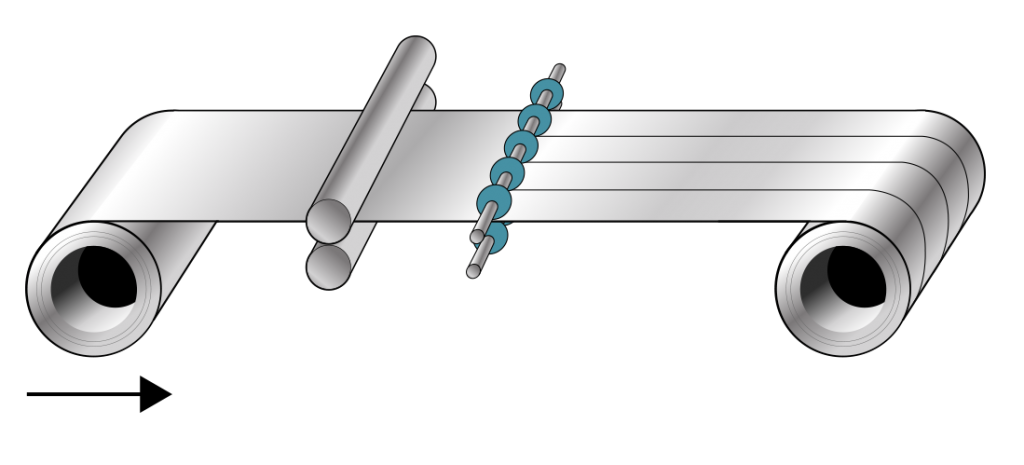

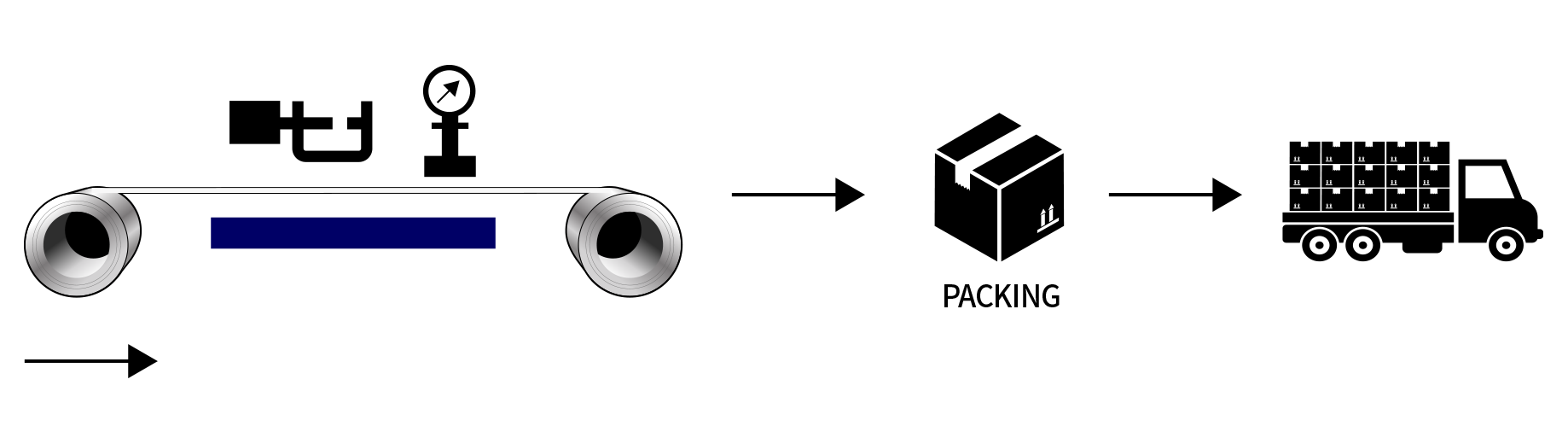

Manufacture Process

Thickness Tolerances

Width Tolerances

Surface Roughness

Flatness Deviation

Straightness Deviation

Hubei Baomit Steel Materials Co., Ltd.

Leading manufacturer of hardened and tempered spring steel strips and sheets. Baomit strip steel stands for precision, quality and high performance. Our materials are excellent in terms of comprehensive delivery indicators, such as straightness, flatness, mechanical properties and metallographic uniformity.