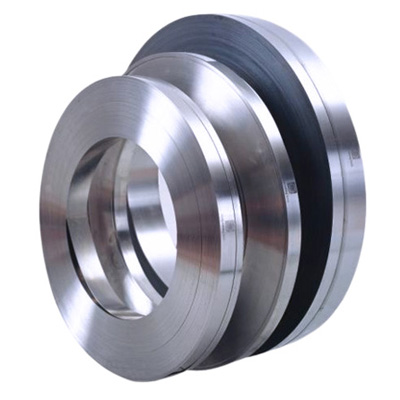

Hardened and Tempered Stainless Steel Strips

Baomit offers hardened and tempered martensitic stainless steel strips and sheets & plates in 420J2, 440A, 440B and 440C grade. Martensitic steel is a type of stainless steel that is well known for its strength, corrosion resistance, and durability. These qualities make martensitic steel a good choice for a variety of applications, like automotive, machinery parts, and saw blades, for products typically subjected to harsh environments and demanding applications.

| Parameters | Recommendation |

| Thickness Tolerance | T1 – T5 |

| Roughness | Class 1 – 3 |

| Flatness | Class 1 – 4 |

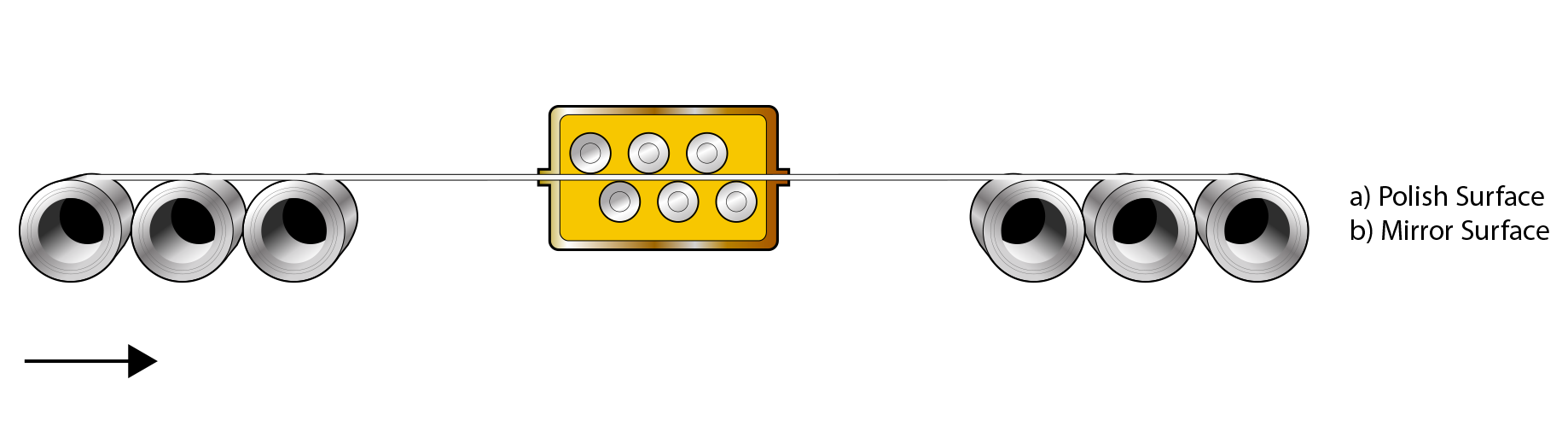

| Surface | Bright, White / Blue / Yellow Polished |

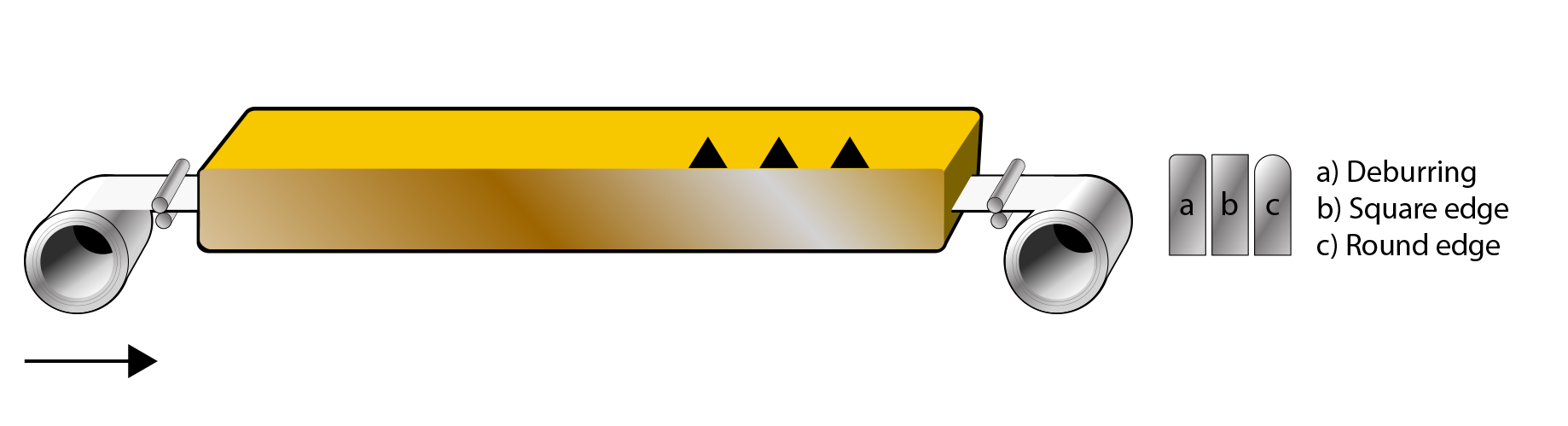

| Edges | Deburring, Square, Round |

| Hardness | 41 – 57 HRC |

| Thickness | 0.10 – 4.50 mm |

| Width | 3 – 460 mm |

| Steel Grade | 420J2, 440A, 440B, 440C |

Our Advantages

• Excellent fatigue resistance

• Excellent punching and stamping properties

• Precise thickness and width tolerances

• Maximum straightness deviation of 1 mm / 3 m

• Good surface finish

• Consistent, uniform microstructure

Steel Grades

| Comparison of Norms | ||

| USA / AISI | EU / EN | Chemical Composition |

| 420J2 | X30Cr13 | C: 0.26-0.40, Si: max 1.0, Mn: max 1.0, Ni: max 0.60, P: max 0.04, S: max 0.03, Cr: 12.0-14.0 |

| 440 | X6Cr13 | C: 0.60-1.20, Si: max 1.0, Mn: max 1.0, Ni: max 0.60, P: max 0.04, S: max 0.03, Cr: 16.0-18.0, Mo: max 0.75 |

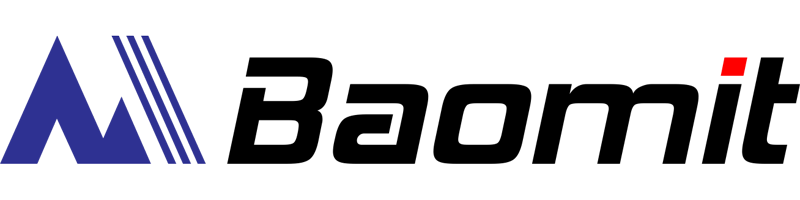

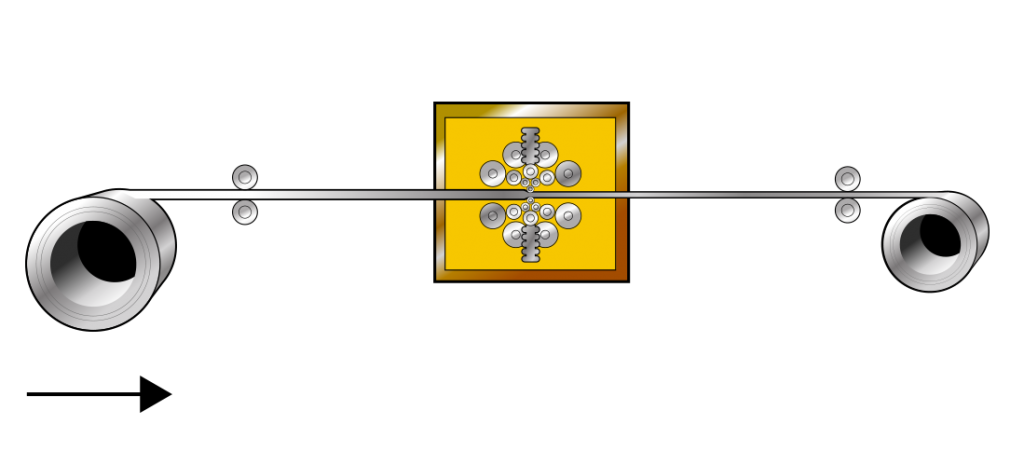

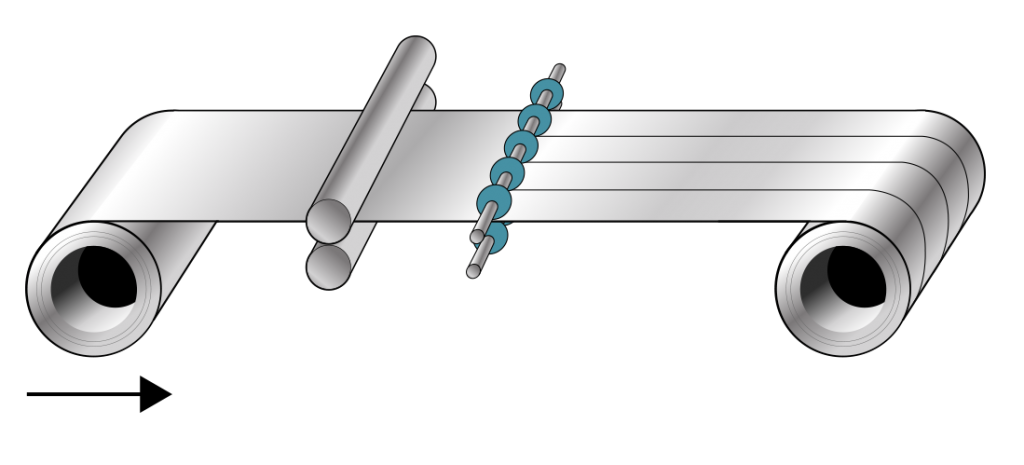

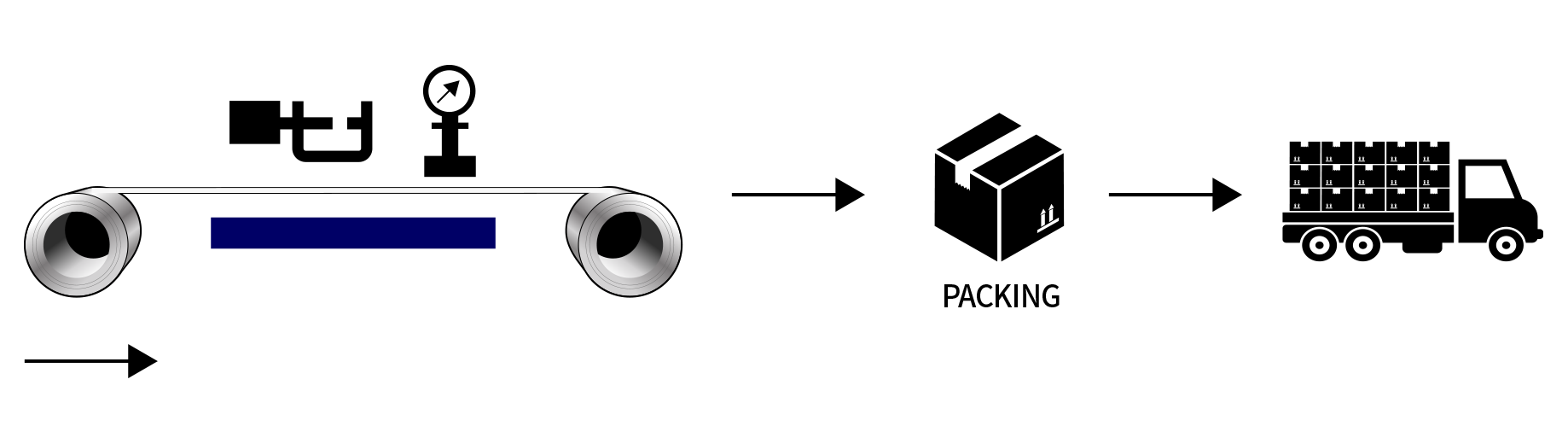

Manufacture Process

Thickness Tolerances

Width Tolerances

Surface Roughness

Flatness Deviation

Straightness Deviation

Hubei Baomit Steel Materials Co., Ltd.

Leading manufacturer of hardened and tempered stainless steel strips. Baomit strip steel stands for precision, quality and high performance. Our materials are excellent in terms of comprehensive delivery indicators, such as straightness, flatness, mechanical properties and metallographic uniformity.