Printing Doctor Blade Steel

Doctor blades play an important role in transferring ink from the anilox roll to the printing plate. A doctor blade removes excess ink from the smooth, non-engraved parts of the anilox roll. Baomit strip steel for doctor blades uses high grade steel and is manufactured with precision, making it a key component for ensuring reliable processes in the printing industry. If you would like to learn more the quality of our strip steel then please contact our steel experts.

| Parameters | Recommendation |

| Thickness Tolerance | T2 |

| Roughness | Class 3 |

| Flatness | Class 3 |

| Surface | Polished White, Blue, Yellow |

| Edges | Round |

| Hardness | 580 – 620 HV |

| Steel Grade | SK95, C100S, 95Cr1, 420J2, 6Cr13 |

Our Advantages

• Excellent wear resistance

• Precise thickness and width tolerances

• Maximum straightness deviation of 1 mm / 3 m

• Good surface finish

• Consistent, specially adapted microstructure

Steel Grades

| Comparison of Norms | ||

| EU / EN | USA / AISI | Chemical Composition |

| C100S | 1095 | C: 0.95-1.05, Si: 0.15-0.35, Mn: 0.30-0.60, Ni: max 0.40, P: max 0.025, S: max 0.025, Cr: max 0.40, Mo: max 0.10 |

| 95Cr1 | / | C: 0.90-1.00, Si: 0.15-0.30, Mn: 0.20-0.40, P: max 0.025, S: max 0.025, Cr: 0.30-0.40 |

| Japan / JIS: 420J2 | C: 0.26-0.40, Si: max 1.0, Mn: max 1.0, Ni: max 0.60, P: max 0.04, S: max 0.03, Cr: 12.0-14.0 | |

Thickness Tolerances

| Thickness (mm) | Tolerances ± mm | ||||

| T1 | T2 | T3 | T4 | T5 | |

| 0.020 – 0.040 | 0.004 | 0.003 | 0.002 | – | – |

| 0.040 – 0.100 | 0.006 | 0.005 | 0.004 | 0.003 | 0.002 |

| 0.100 – 0.125 | 0.007 | 0.005 | 0.004 | 0.003 | 0.002 |

| 0.125 – 0.160 | 0.009 | 0.006 | 0.005 | 0.004 | 0.003 |

| 0.160 – 0.200 | 0.010 | 0.007 | 0.005 | 0.004 | 0.003 |

| 0.200 – 0.250 | 0.011 | 0.008 | 0.006 | 0.004 | 0.003 |

| 0.250 – 0.400 | 0.015 | 0.011 | 0.008 | 0.006 | 0.004 |

| 0.400 – 0.600 | 0.020 | 0.014 | 0.010 | 0.007 | 0.005 |

| 0.600 – 0.800 | 0.023 | 0.017 | 0.012 | 0.008 | 0.006 |

| 0.800 – 1.000 | 0.027 | 0.019 | 0.013 | 0.009 | 0.007 |

| 1.000 – 1.250 | 0.034 | 0.024 | 0.017 | 0.012 | 0.008 |

| 1.250 – 1.600 | 0.039 | 0.028 | 0.020 | – | – |

| 1.600 – 1.750 | 0.046 | 0.033 | 0.023 | – | – |

Width Tolerances

| Thickness (mm) | Width (mm) | Tolerances ± mm | ||

| W1 | W2 | W3 | ||

| ≤0.25 | ≤50 | 0.10 | 0.07 | 0.05 |

| 50 – 125 | 0.15 | 0.11 | 0.07 | |

| >125 | 0.20 | 0.15 | 0.10 | |

| 0.25 – 0.50 | ≤50 | 0.15 | 0.11 | 0.07 |

| 50 – 125 | 0.20 | 0.15 | 0.10 | |

| >125 | 0.25 | 0.20 | 0.15 | |

| 0.50 – 1.00 | ≤50 | 0.20 | 0.15 | 0.10 |

| 50 – 125 | 0.25 | 0.20 | 0.15 | |

| >125 | 0.30 | 0.25 | 0.15 | |

| 1.00 – 1.60 | ≤50 | 0.20 | 0.15 | 0.10 |

| 50 – 125 | 0.30 | 0.25 | 0.15 | |

| >125 | 0.35 | 0.25 | 0.20 | |

| 1.60 – 1.75 | ≤50 | 0.30 | 0.20 | 0.15 |

| 50 – 125 | 0.35 | 0.30 | 0.20 | |

| >125 | 0.40 | 0.30 | 0.20 | |

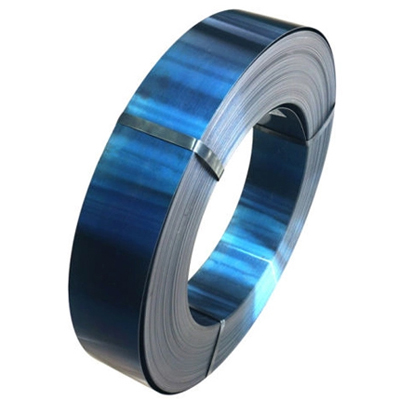

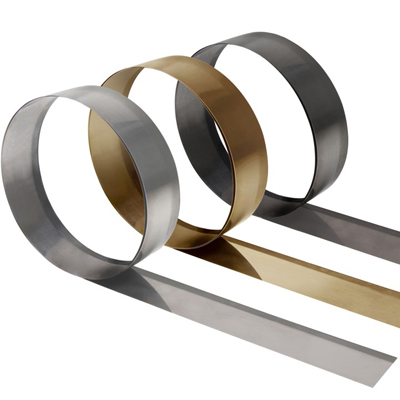

Surface Roughness

Available in white, blue and yellow polished.

| Thickness (mm) | Roughness | ||

| Class 1 | Class 2 | Class 3 | |

| ≤0.50 | Ra≤ 0.30 µm Rt≤ 3.00 µm | Ra≤0.25 µm Rt≤ 2.50 µm | Ra≤ 0.20 µm Rt≤ 2.00 µm |

| 0.50 – 1.00 | Ra≤ 0.35 µm Rt≤ 3.50 µm | Ra≤ 0.25 µm Rt≤ 2.50 µm | Ra≤ 0.20 µm Rt≤ 2.00 µm |

| 1.00 – 1.75 | Ra≤ 0.40 µm Rt≤ 4.00 µm | Ra≤ 0.30 µm Rt≤ 3.00 µm | Ra≤ 0.30 µm Rt≤ 3.00 µm |

Flatness Deviation

Maximum flatness deviation per inch strip width.

| Thickness (mm) | Flatness Deviation | |||

| Class 1 | Class 2 | Class 3 | Class 4 | |

| 0.02 – 0.10 | P60 | P50 | P40 | P30 |

| 0.10 – 0.25 | P50 | P40 | P30 | P20 |

| 0.25 – 0.50 | P40 | P30 | P20 | P10 |

| 0.50 – 1.75 | P35 | P25 | P15 | P10 |

Straightness Deviation

| Strip Width (mm) | Measured Length (3m) | ||

| Class 1 | Class 2 | Class 3 | |

| ≤50 | 3 mm | 2 mm | 1 mm |

| 50 – 125 | 3 mm | 2 mm | 1 mm |

| >125 | 3 mm | 2 mm | 1 mm |

Hubei Baomit Steel Materials Co., Ltd.

China Leading Manufacturer of Hardened and Tempered (H & T) Strip Steel, ISO 9001: 2015 Certified