80CrV2 1.2235 Spring Steel Strip

| Parameters | Recommendation |

| Steel Grade | 80CrV2 |

| Brand | BAOMIT |

| Certification | ISO9001:2015 |

| Hardness | 48 – 52 HRC |

| Surface Finish | Polished bright, white, blue and yellow |

| Edges | Slit, square or round |

| Thickness Tolerance | +/- 0.005 |

| Width Tolerance | +/- 0.10 |

| Camber | Max 1mm per 3m |

Our Advantages

• Excellent fatigue resistance

• Excellent punching and stamping properties

• Precise thickness and width tolerances

• Maximum straightness deviation of 1 mm / 3 m

• Good surface finish

• Consistent, uniform microstructure

Chemical Composition of 80CrV2 (1.2235)

| C | Si | Mn | Ni | P | S | Cr | Mo | V |

| 0.75-0.85 | 0.15-0.35 | 0.30-0.50 | max 0.40 | max 0.025 | max 0.025 | 0.40-0.60 | max 0.10 | 0.15-0.25 |

Thickness Tolerances

| Thickness (mm) | Tolerances ± mm | ||||

| T1 | T2 | T3 | T4 | T5 | |

| 0.020 - 0.040 | 0.004 | 0.003 | 0.002 | - | - |

| 0.040 - 0.100 | 0.006 | 0.005 | 0.004 | 0.003 | 0.002 |

| 0.100 - 0.125 | 0.007 | 0.005 | 0.004 | 0.003 | 0.002 |

| 0.125 - 0.160 | 0.009 | 0.006 | 0.005 | 0.004 | 0.003 |

| 0.160 - 0.200 | 0.010 | 0.007 | 0.005 | 0.004 | 0.003 |

| 0.200 - 0.250 | 0.011 | 0.008 | 0.006 | 0.004 | 0.003 |

| 0.250 - 0.400 | 0.015 | 0.011 | 0.008 | 0.006 | 0.004 |

| 0.400 - 0.600 | 0.020 | 0.014 | 0.010 | 0.007 | 0.005 |

| 0.600 - 0.800 | 0.023 | 0.017 | 0.012 | 0.008 | 0.006 |

| 0.800 - 1.000 | 0.027 | 0.019 | 0.013 | 0.009 | 0.007 |

| 1.000 - 1.250 | 0.034 | 0.024 | 0.017 | 0.012 | 0.008 |

| 1.250 - 1.600 | 0.039 | 0.028 | 0.020 | - | - |

| 1.600 - 1.750 | 0.046 | 0.033 | 0.023 | - | - |

Width Tolerances

| Thickness (mm) | Width (mm) | Tolerances ± mm | ||

| W1 | W2 | W3 | ||

| ≤0.25 | ≤50 | 0.10 | 0.07 | 0.05 |

| 50 - 125 | 0.15 | 0.11 | 0.07 | |

| >125 | 0.20 | 0.15 | 0.10 | |

| 0.25 - 0.50 | ≤50 | 0.15 | 0.11 | 0.07 |

| 50 - 125 | 0.20 | 0.15 | 0.10 | |

| >125 | 0.25 | 0.20 | 0.15 | |

| 0.50 - 1.00 | ≤50 | 0.20 | 0.15 | 0.10 |

| 50 - 125 | 0.25 | 0.20 | 0.15 | |

| >125 | 0.30 | 0.25 | 0.15 | |

| 1.00 - 1.60 | ≤50 | 0.20 | 0.15 | 0.10 |

| 50 - 125 | 0.30 | 0.25 | 0.15 | |

| >125 | 0.35 | 0.25 | 0.20 | |

| 1.60 - 1.75 | ≤50 | 0.30 | 0.20 | 0.15 |

| 50 - 125 | 0.35 | 0.30 | 0.20 | |

| >125 | 0.40 | 0.30 | 0.20 | |

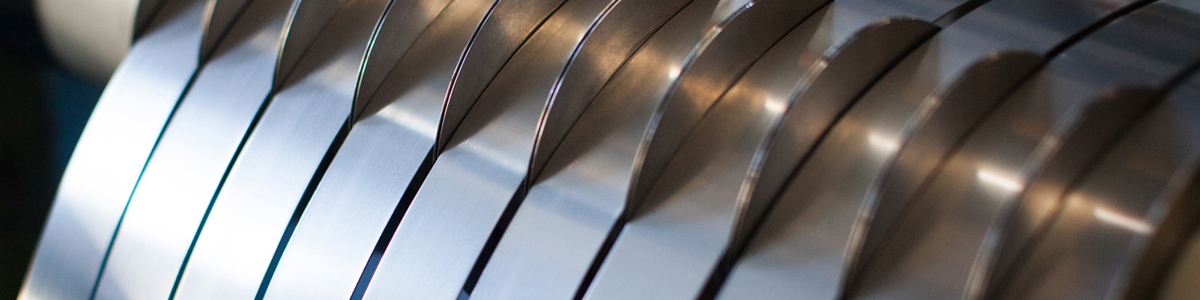

Surface Roughness

Available in polished bright, white, blue and yellow.

| Thickness (mm) | Roughness | ||

| Class 1 | Class 2 | Class 3 | |

| ≤0.50 | Ra≤ 0.30 µm Rt≤ 3.00 µm | Ra≤0.25 µm Rt≤ 2.50 µm | Ra≤ 0.20 µm Rt≤ 2.00 µm |

| 0.50 - 1.00 | Ra≤ 0.35 µm Rt≤ 3.50 µm | Ra≤ 0.25 µm Rt≤ 2.50 µm | Ra≤ 0.20 µm Rt≤ 2.00 µm |

| 1.00 - 1.75 | Ra≤ 0.40 µm Rt≤ 4.00 µm | Ra≤ 0.30 µm Rt≤ 3.00 µm | Ra≤ 0.30 µm Rt≤ 3.00 µm |

Flatness Deviation

Maximum flatness deviation per inch strip width.

| Thickness (mm) | Flatness Deviation | |||

| Class 1 | Class 2 | Class 3 | Class 4 | |

| 0.02 - 0.10 | P60 | P50 | P40 | P30 |

| 0.10 - 0.25 | P50 | P40 | P30 | P20 |

| 0.25 - 0.50 | P40 | P30 | P20 | P10 |

| 0.50 - 1.75 | P35 | P25 | P15 | P10 |

Straightness Deviation

| Strip Width (mm) | Measured Length (3m) | ||

| Class 1 | Class 2 | Class 3 | |

| ≤50 | 3 mm | 2 mm | 1 mm |

| 50 - 125 | 3 mm | 2 mm | 1 mm |

| >125 | 3 mm | 2 mm | 1 mm |

80CrV2 Spring Steel Strip

Place of Origin: China

Manufacturer: Hubei Baomit Steel Materials Co., Ltd.

Steel Grade: 80CrV2 (1.2235)

Equivalent Grades:

Supply Condition: Hardened and Tempered (H & T)

Applications: Springs, blades, strippers, scrapers

Brand: BAOMIT

Min Order: 1 Ton

Package: Pallet

Delivery Time: 4-5 weeks

Payment Term: L/C, T/T, Western Union

Production Capacity: 300 tons per month

"Baomit strip steel stands for precision, quality and high performance. Our materials are excellent in terms of comprehensive delivery indicators, such as straightness, flatness, mechanical properties and metallographic uniformity."