Manufacturing Capabilities

Precision Strip Steel: High Carbon Steel Strips, Alloyed Steel Strips, Hardened and Tempered Steel Strips.

Baomit excels as the global leader and expert in precision steel strips since 2011.

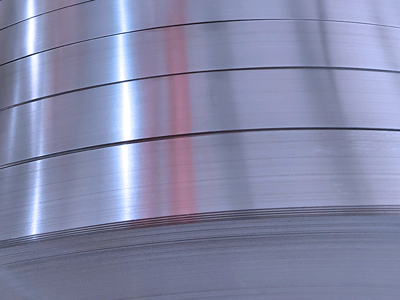

Cold Rolling

Cold Rolling

Cold rolled strip is a popular metal product within the aerospace, automotive, and agricultural industry where it is stamped, deep drawn, or formed using other methods for various applications. Baomit transforms hot rolled coils into precision cold rolled strips.

• Precision Rolling to Tolerances

.0003″ to .125″ Gauge (0.00762mm – 3.175mm)

• Thickness Tolerance

+/- .0005" (+/- 0.0127mm)

• Width Range

.020″ – 14″ (0.508mm – 355.6mm)

• Width Tolerance

+/- .005" (+/- 0.127mm)

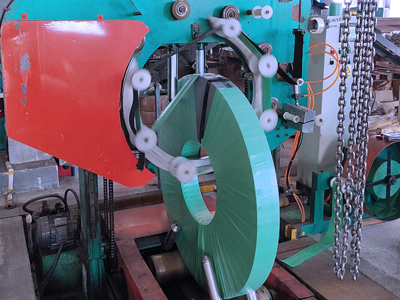

Slitting

Slitting

Slitting is a process to separate a material at finish gauge and temper into the width as required. Apart from width, edge condition, coil support, coil inner diameter, coil size are all characteristics of the final product that are realized during final slitting.

Edging

Edging

Long experience in edge’s trimming allows us to offer a wide range of standard and customers’ specifications.

• A.I.S.I. No. 1 – Round Edge

• A.I.S.I No. 3 – Slit Edge

• A.I.S.I. No. 5 - Square Edge

Hardening and Tempering

Hardening and Tempering

This is our original and actual core business.

Hardened and tempered strip steel has comprehensive mechanical properties with good strength, hardness and toughness. We properly harden and temper carbon steel strips to satisfy the most demanding specifications of our customers.

Packaging

Packaging

Each strip coil will be wrapped with Vapor Phase Inhibited (VPI) plastic or paper for protection and anti-corrosion. On each pallet we have proper labelling with full traceability: quality, size, weight, customer’s order and part number and our production lot.