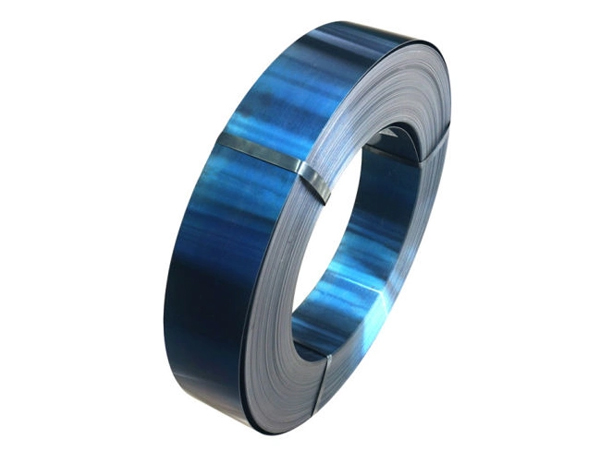

HIGH CARBON STEEL STRIPS

High carbon steel strips are valued for ideal strength properties and operate at significantly higher levels than the mild steel grades. High carbon steel strips & steel coils are almost always used in those applications where wear characteristics and higher strengths are important.

Steel Grades

Supply Conditions

• Hot Rolled

• Cold Rolled

• Annealed

• Spheroidize Annealed

Mechanical Properties

Here after are shown standard mechanical properties of high carbon steel strips. Different values can be discussed with our team of experts that will help our customers to get better results in their production. Not sure where to start? Contact a Specialist

| USA | EU / NUMBER | C | Si | Mn | P | S | Cr | Mo | Ni |

| 1010 | C10E / 1.1121 | 0.07 - 0.13 | Max 0.40 | 0.30 - 0.60 | Max 0.035 | Max 0.035 | |||

| 1015 | C15E / 1.1141 | 0.12 - 0.18 | Max 0.40 | 0.30 - 0.60 | Max 0.035 | Max 0.035 | |||

| 1045 | C45E / 1.1191 | 0.42 - 0.50 | Max 0.40 | 0.50 - 0.80 | Max 0.035 | Max 0.035 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1050 | C50E / 1.1206 | 0.47 - 0.55 | Max 0.40 | 0.60 - 0.90 | Max 0.035 | Max 0.035 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1055 | C55S / 1.1204 | 0.52 - 0.60 | 0.15 - 0.35 | 0.60 - 0.90 | Max 0.025 | Max 0.025 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1060 | C60S / 1.1211 | 0.57 - 0.65 | 0.15 - 0.35 | 0.60 - 0.90 | Max 0.025 | Max 0.025 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1070 | C67S / 1.1231 | 0.65 - 0.73 | 0.15 - 0.35 | 0.60 - 0.90 | Max 0.025 | Max 0.025 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1075 | C75S / 1.1248 | 0.70 - 0.80 | 0.15 - 0.35 | 0.60 - 0.90 | Max 0.025 | Max 0.025 | Max 0.40 | Max 0.10 | Max 0.40 |

| 1095 | C100S / 1.1274 | 0.95 - 1.05 | 0.15 - 0.35 | 0.30 - 0.60 | Max 0.025 | Max 0.025 | Max 0.40 | Max 0.10 | Max 0.40 |

Hubei Baomit Steel Materials Co., Ltd.

Baomit excels as the global leader and an expert in cold rolled precision steel strips since 2011. Our experienced processing capabilities give our customers access to the tighter tolerances with higher precision. Baomit’s team of experts personalize material solutions to suit your precise needs and manufacturing processes. We offer precision steel strips, foils, aligned with reliable delivery for multiple applications in a variety of industries, including aerospace, automotive, oil & gas, power...

Our Service Center Processing Capabilities

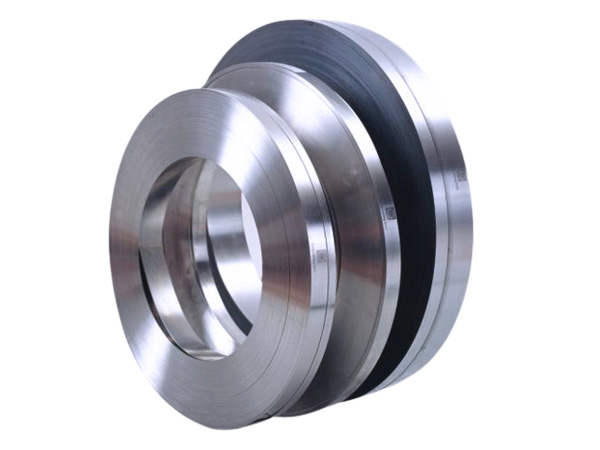

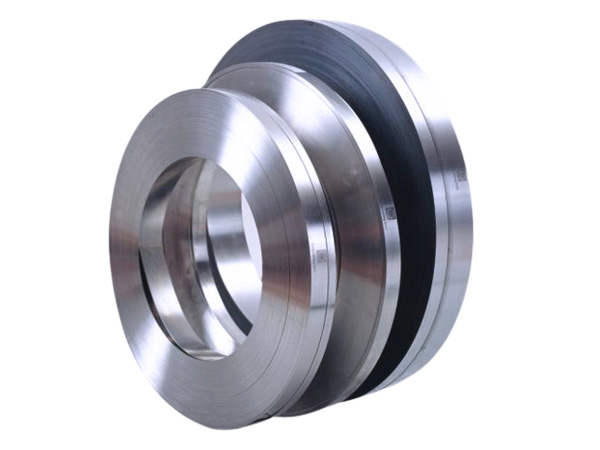

| Cold Rolling

Cold rolled strip is a popular metal product within the aerospace, automotive, and agricultural industry where it is stamped, deep drawn, or formed using other methods for various applications. Baomit transforms hot rolled coils into precision cold rolled strips.

• Precision Rolling to Tolerances

.0003″ to .125″ Gauge (0.00762mm – 3.175mm)

• Thickness Tolerance

+/- .0005" (+/- 0.0127mm)

• Width Range

.020″ – 14″ (0.508mm – 355.6mm)

• Width Tolerance

+/- .005" (+/- 0.127mm)

| Slitting

Slitting is a process to separate a material at finish gauge and temper into the width as required. Apart from width, edge condition, coil support, coil inner diameter, coil size are all characteristics of the final product that are realized during final slitting.

| Hardening and Tempering

This is our original and actual core business. Hardened and tempered steel strips has comprehensive mechanical properties with good strength, hardness and toughness. We properly harden and temper carbon steel strips to satisfy the most demanding specifications of our customers.

| Quality Testing

At Baomit, our team of experts and engineers are expertly trained in producing to exact specifications. We control critical aspects of our strip steel materials, including properties, dimensions, and chemistries, leading to consistency and higher performance.

Looking for an experienced materials partner to extend your supply chain?

Rich experience working with cold rolled precision steel strips in multiple industries, has led us to the forefront in applications. You’ll be assisted by our team of experts each time, enabling you to establish a strong working relationship. Contact a Specialist!

YOU MAY ALSO BE INTERESTED IN THESE PRODUCTS